Apple cider has become increasingly popular in recent years, and many cideries are now producing large quantities of cider to meet the growing demand. However, producing cider on a large scale requires the right tools and equipment to ensure consistent quality and efficiency. In this blog post, we’ll take a closer look at the essential tools and equipment needed to produce apple cider in large amounts.

- Apple Crushers

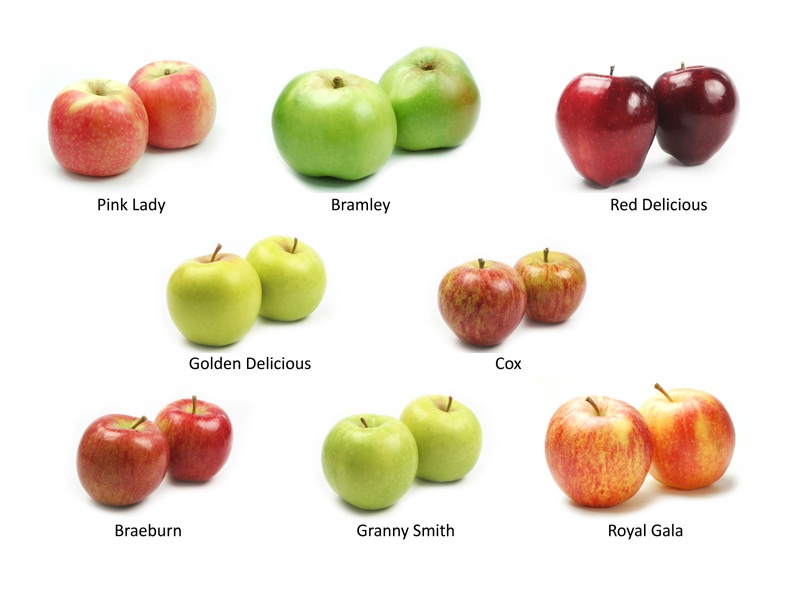

The first step in making apple cider is to crush the apples to extract their juice. This is usually done using an apple crusher, which can be either manual or electric. Manual apple crushers are simple machines that require a lot of physical effort to operate. They consist of a hopper that holds the apples, and a set of blades that chop the apples into small pieces.

Electric apple crushers are more efficient and require less effort to operate. They use a motor to power a set of blades that crush the apples into pulp. Electric apple crushers are also available in various sizes, making it easier to choose one that fits the specific needs of your cidery.

- Apple Presses

Once the apples have been crushed, the next step is to extract the juice from the pulp. This is done using an apple press. An apple press uses pressure to extract the juice from the pulp. The pulp is placed in a bag or a cheesecloth, and the bag is then placed inside the press. The press is then tightened, and the juice is squeezed out of the pulp.

There are several types of apple presses available, including manual presses and hydraulic presses. Manual presses are simple machines that require a lot of physical effort to operate. They consist of a press that is powered by a crank. Hydraulic presses are more efficient and require less effort to operate. They use a hydraulic cylinder to apply pressure to the pulp.

- Fermentation Vessels

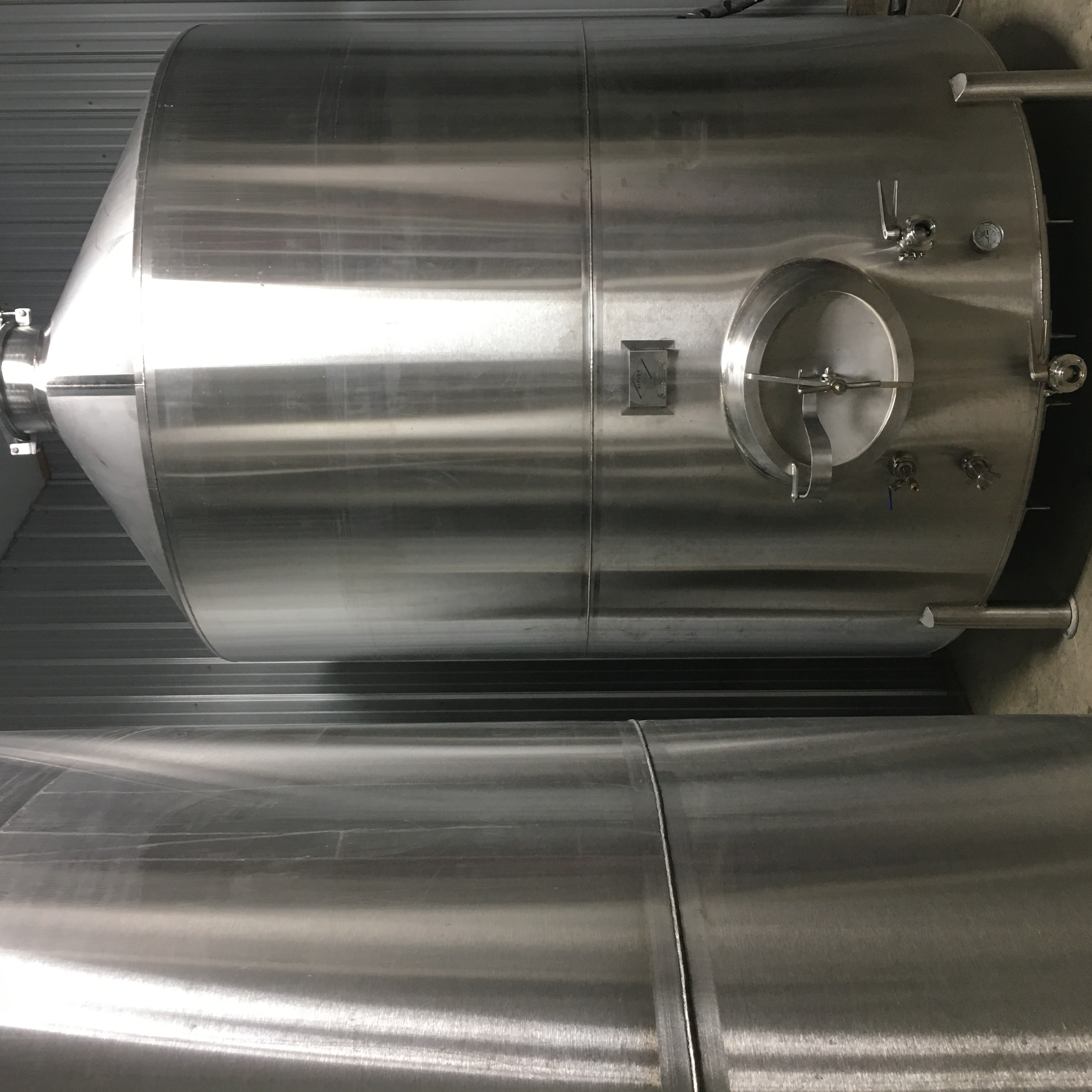

After the juice has been extracted from the pulp, it is ready to be fermented. Fermentation vessels are used to store the juice during the fermentation process. The most common types of fermentation vessels are stainless steel tanks and oak barrels.

Stainless steel tanks are the most popular choice for large-scale cider production. They are easy to clean and maintain, and they can be fitted with temperature controls to regulate the fermentation process.

Oak barrels are also used for cider fermentation, particularly for cideries that want to produce a more traditional style of cider. Oak barrels add a unique flavor to the cider, but they require more maintenance than stainless steel tanks.

- Yeast and Nutrients

Yeast is a crucial component of the cider-making process. It is the yeast that converts the sugar in the apple juice into alcohol. There are several types of yeast available, each with its own unique characteristics.

In addition to yeast, nutrients are also important for the fermentation process. Yeast nutrients are added to the apple juice to help the yeast ferment more efficiently. Nutrients can also help prevent off-flavors and improve the overall quality of the cider.

- Filtration Equipment

Filtration equipment is used to clarify the cider before bottling. There are several types of filtration equipment available, including plate and frame filters, cartridge filters, and crossflow filters.

Plate and frame filters are the most common type of filtration equipment used in cider production. They consist of a series of plates that are lined with filter media. The cider is pumped through the plates, and the filter media captures any particles or sediment.

Cartridge filters are similar to plate and frame filters, but they use disposable filter cartridges instead of plates.

Crossflow filters are the most efficient type of filtration equipment. They use a porous membrane to filter the cider, and they can filter large volumes of cider quickly.

- Bottling Equipment

Once the cider has been clarified, it is ready to be bottled. Bottling equipment is essential for large-scale cider production, as it allows cideries to bottle large quantities of cider quickly and efficiently.

There are several types of bottling equipment available, including gravity fillers, counter pressure fillers, and rotary fillers.

Gravity fillers are the most basic type of bottling equipment. They consist of a tank that holds the cider, and a tube that leads to the bottles. The bottles are placed under the tube, and the cider flows into the bottles by gravity.

Counter pressure fillers are more advanced than gravity fillers. They use a pressurized system to fill the bottles with cider. This system helps to prevent oxidation and carbonation loss during the bottling process.

Rotary fillers are the most efficient type of bottling equipment. They use a series of rotating spouts to fill multiple bottles at once. This allows cideries to bottle large quantities of cider quickly and efficiently.

- Pasteurization Equipment

Pasteurization equipment is used to kill any bacteria or microorganisms that may be present in the cider before bottling. This helps to ensure that the cider remains fresh and stable during storage.

There are two main types of pasteurization equipment: flash pasteurizers and tunnel pasteurizers.

Flash pasteurizers use a high temperature for a short period of time to kill bacteria in the cider. The cider is heated to a temperature of 70-80°C for a few seconds, and then cooled rapidly.

Tunnel pasteurizers use a lower temperature for a longer period of time to kill bacteria in the cider. The cider is heated to a temperature of 60-65°C for several minutes, and then cooled slowly.

Producing apple cider on a large scale requires the right tools and equipment to ensure consistent quality and efficiency. Apple crushers, apple presses, fermentation vessels, yeast and nutrients, filtration equipment, bottling equipment, and pasteurization equipment are all essential components of a cider production facility.

When selecting equipment for a cidery, it is important to consider the specific needs of the cidery and the types of cider that will be produced. The equipment should be easy to clean and maintain, and should be able to handle the volume of cider that will be produced.

With the right tools and equipment, cideries can produce high-quality cider that meets the growing demand for this popular beverage. Whether producing traditional cider or experimenting with new flavors and styles, the right equipment is essential for success in the cider industry.